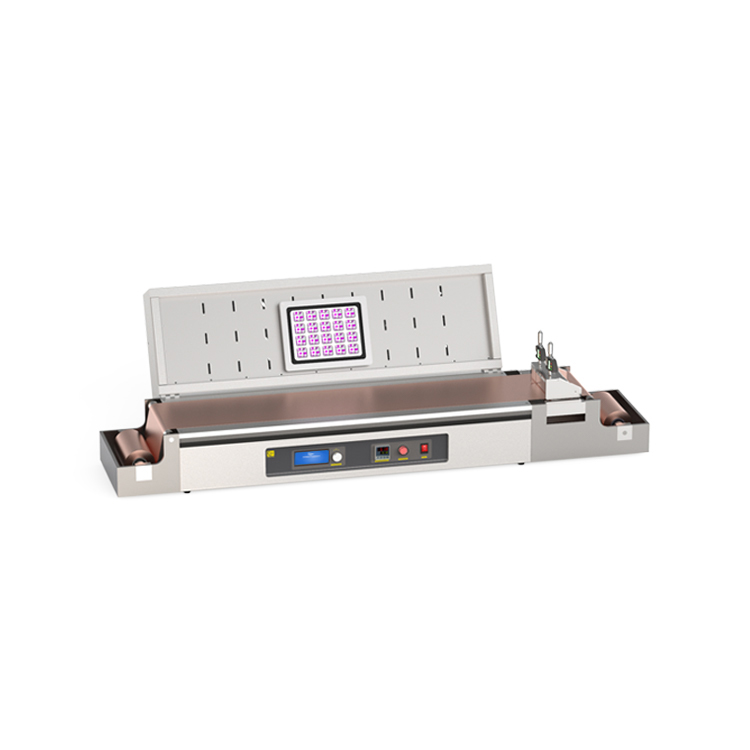

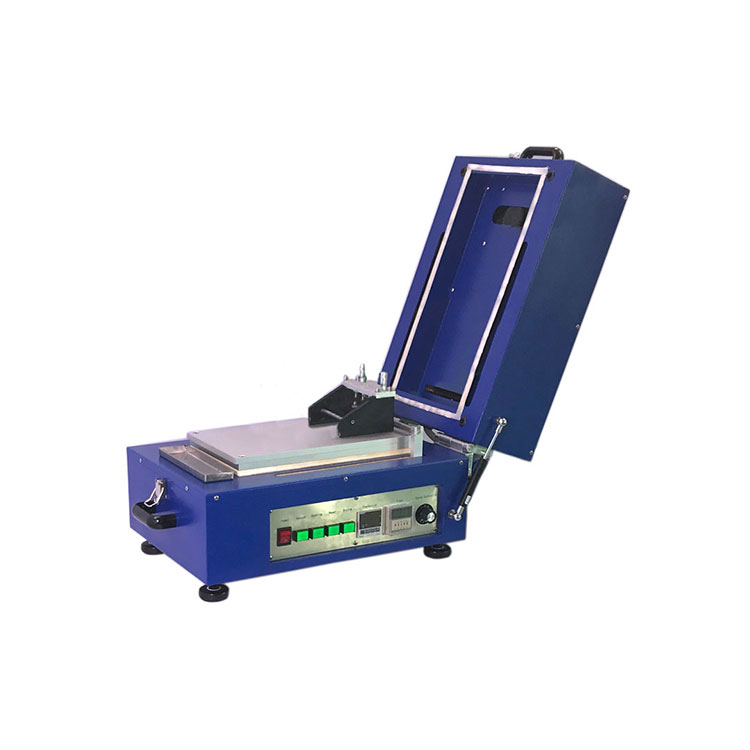

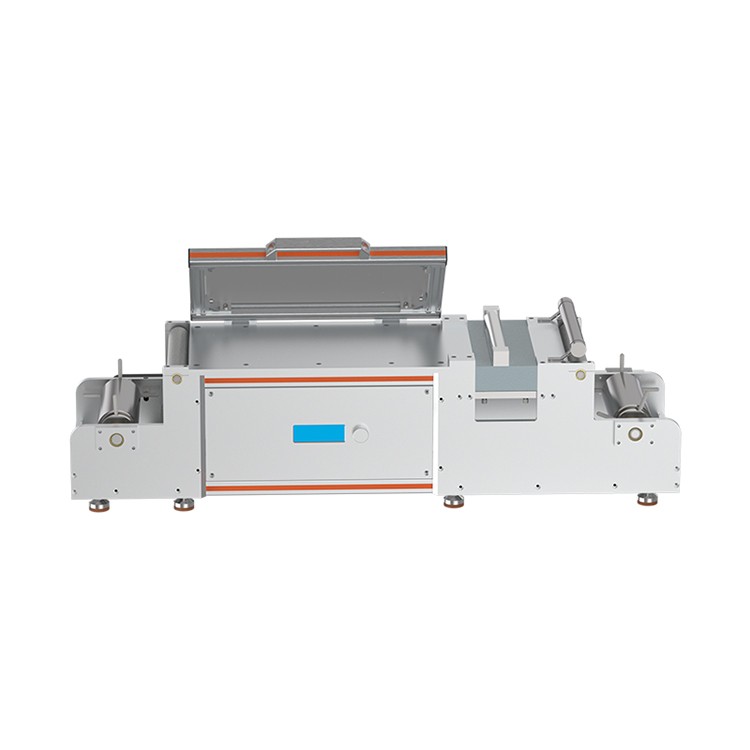

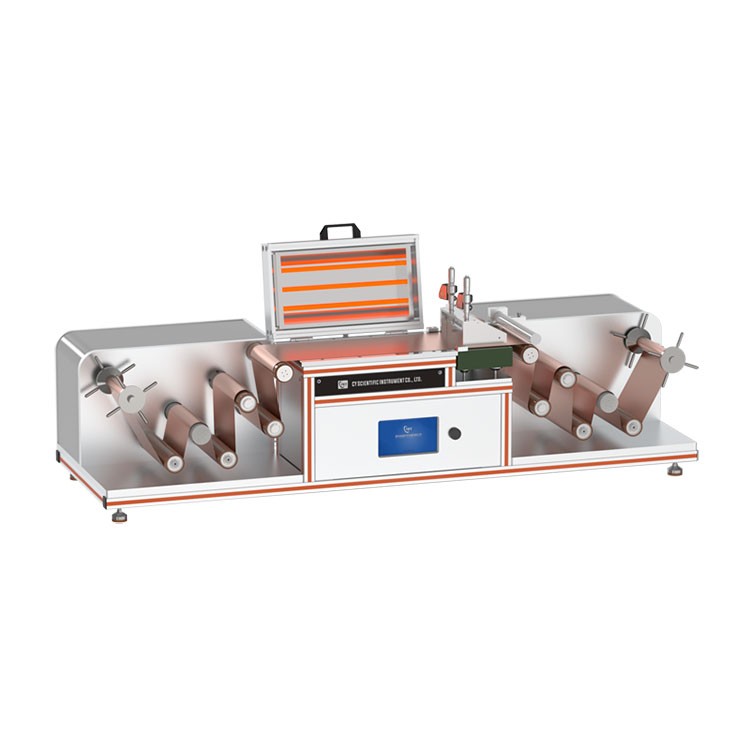

Compact automatic battery electrode coating system integrates the functions/features of reeling in & out, slurry feeder, coating blade, baking oven, and final electrode winding (reeling in). It can coat electrode sheets up to 160mm in width and 500 meters in length automatically.

Compact automatic battery electrode coating system specifications:

Working Voltage | 208 – 240VAC, 50/60Hz, Single phase |

Max. Power Consumption | 3 KW |

Coating Thickness Precison | +/- 0.006 mm |

Coating Width | 50-160 mm Adjustable |

Coating thickness | Usually 30~200μm Depends on different slurry viscosity |

Coating Speed | 0-200 mm/minute |

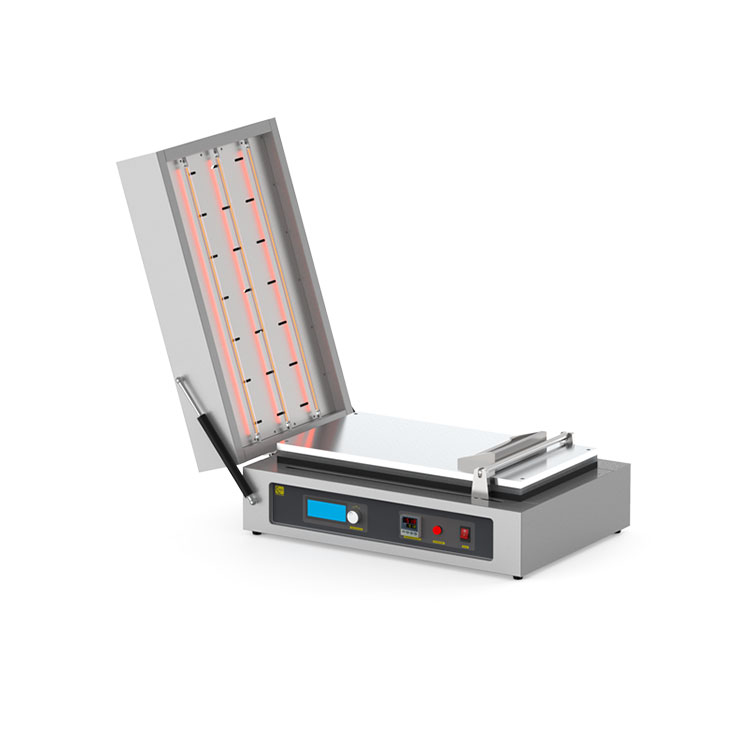

Drying Oven Temperature | 40-150°C +/- 1°C |

Reel-out/in System | 50mm (ID) |

Max. Rolled Diameter | 200mm (OD) |

Max. Coating Length | · Depending on the coating and substrate thickness. · Typically, 10um thick foil with 100um coating can get 500 meters of electrode length coated per run |

Slurry Stirring | SS316 Moving Rod |

Dimensions | 1000mm(L) x 650mm(W) x 650mm(H) – footprint The R2R coater can be placed into a glove-box for air sensitive material |

Net Weight | 400 kg (882 lbs) |

Warranty | · One year limited warranty with lifetime support · Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

Application Notes | Please use Acetone to clean and dry the doctor blade, slurry feeder, and roller to avoid rusting. |