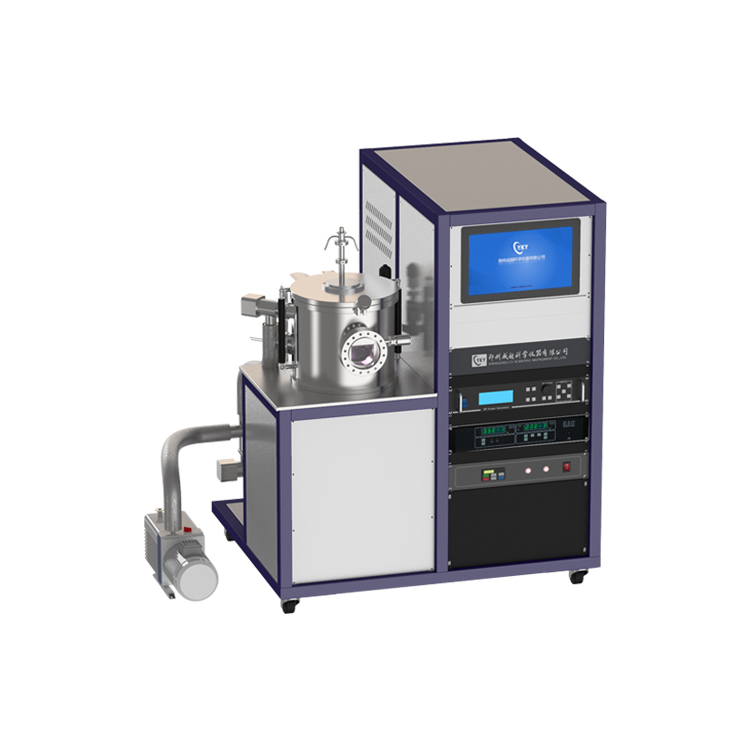

Input Power | 1.220VAC 50/60Hz, single phase

2.2000W (including pump) |

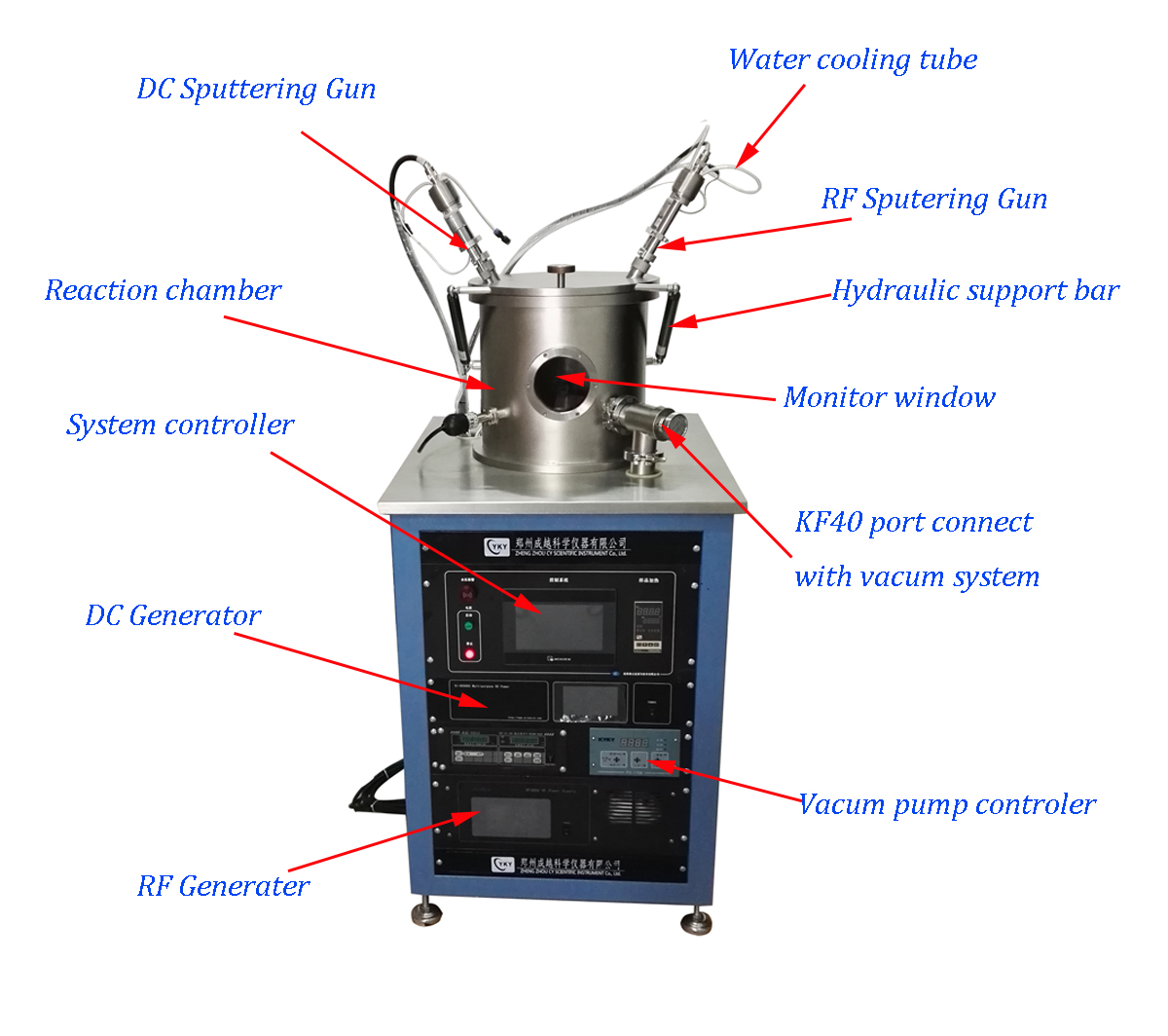

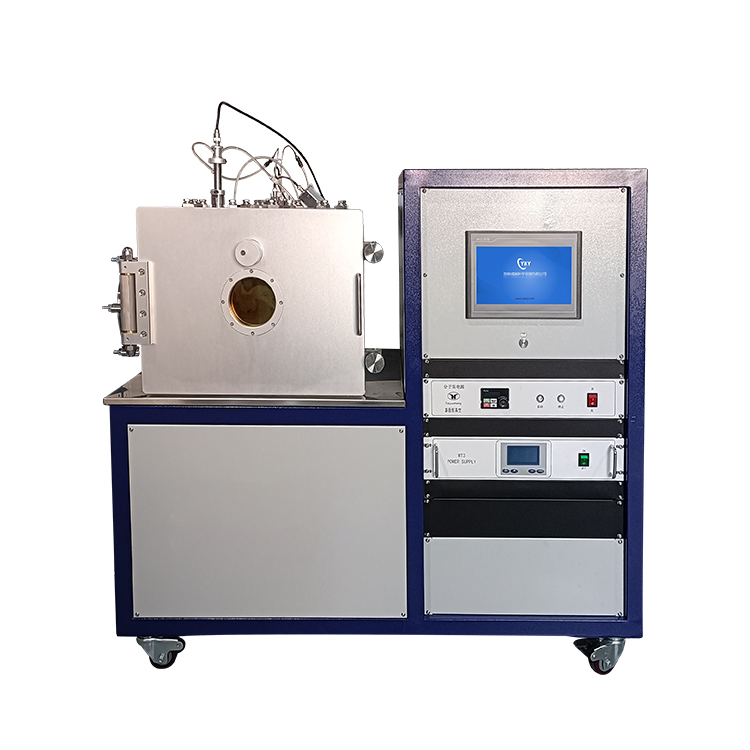

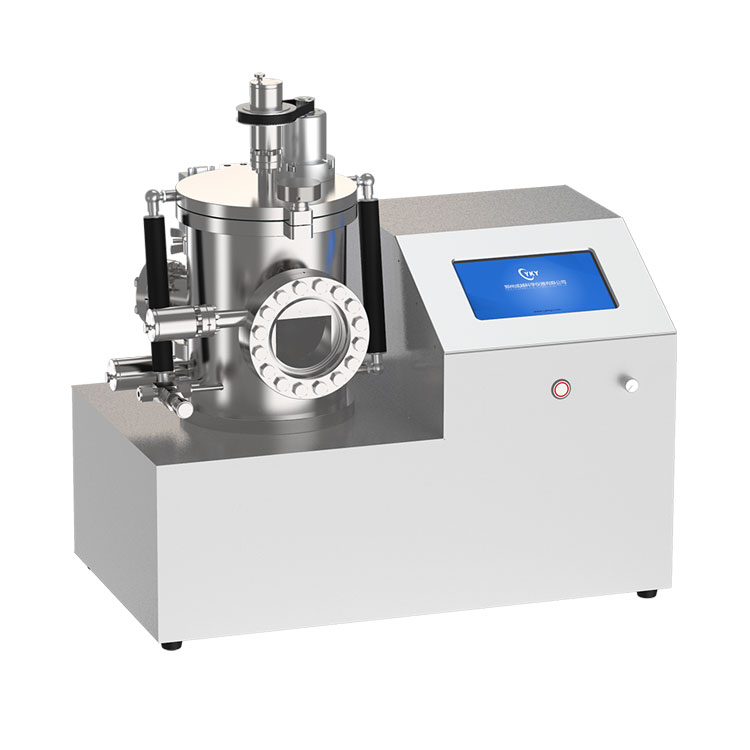

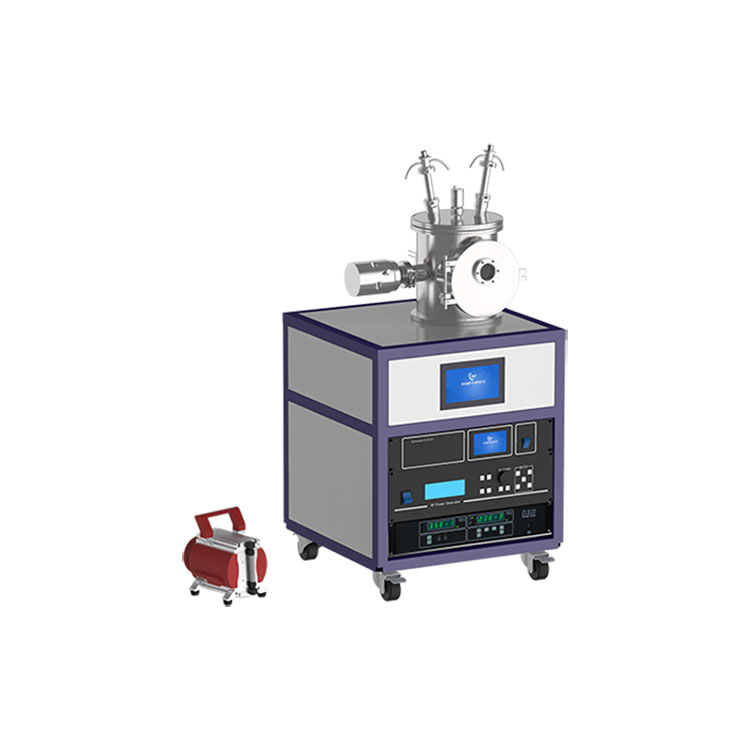

Source Power | 1.Two sputtering power sources are integrated into one control box |

2. DC source: 500W for coating metallic materials |

3.RF source: 600W with automatching for coating non-metallic materials ( Center) |

4.Compact 300 RF source is available at extra cost |

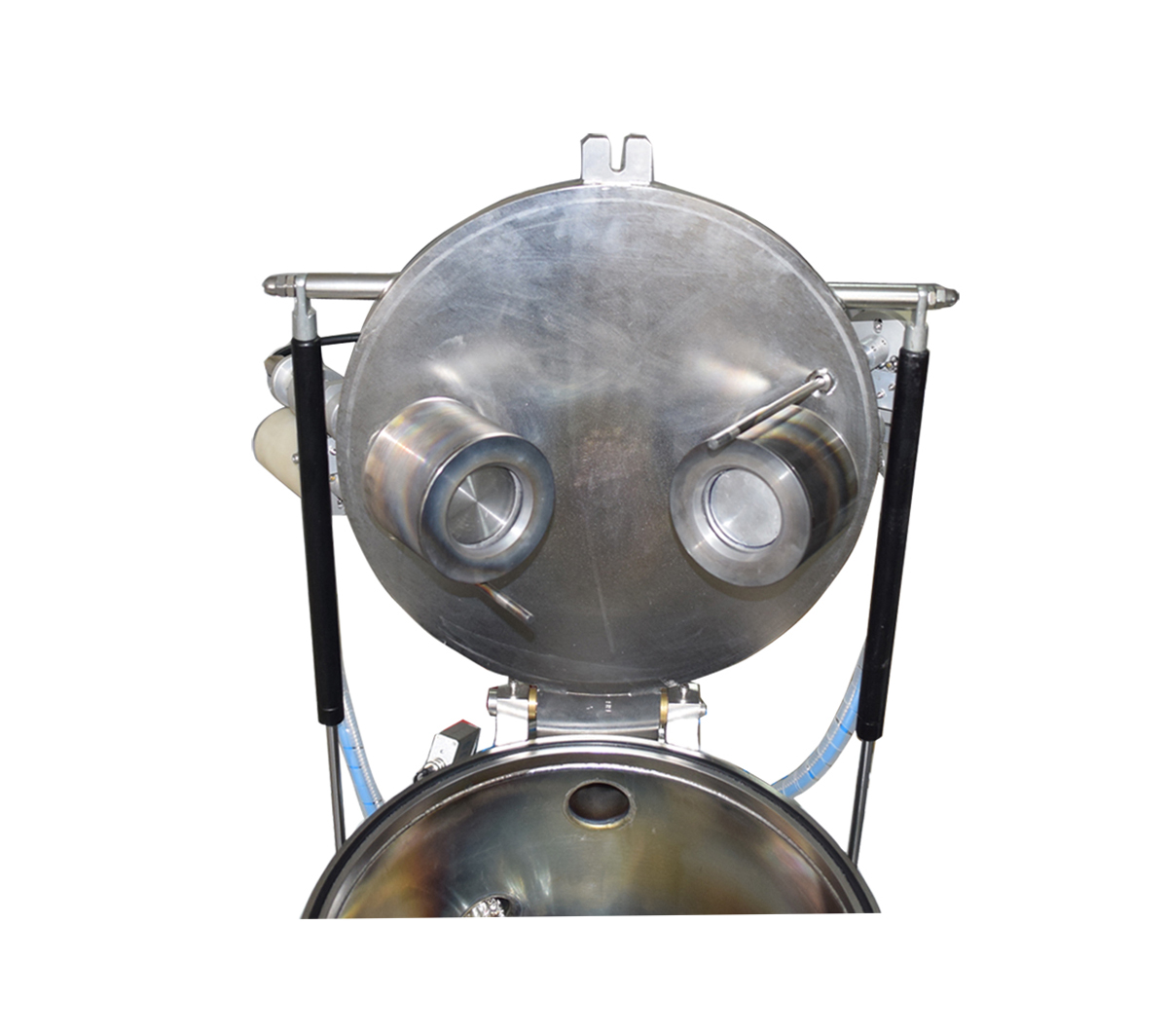

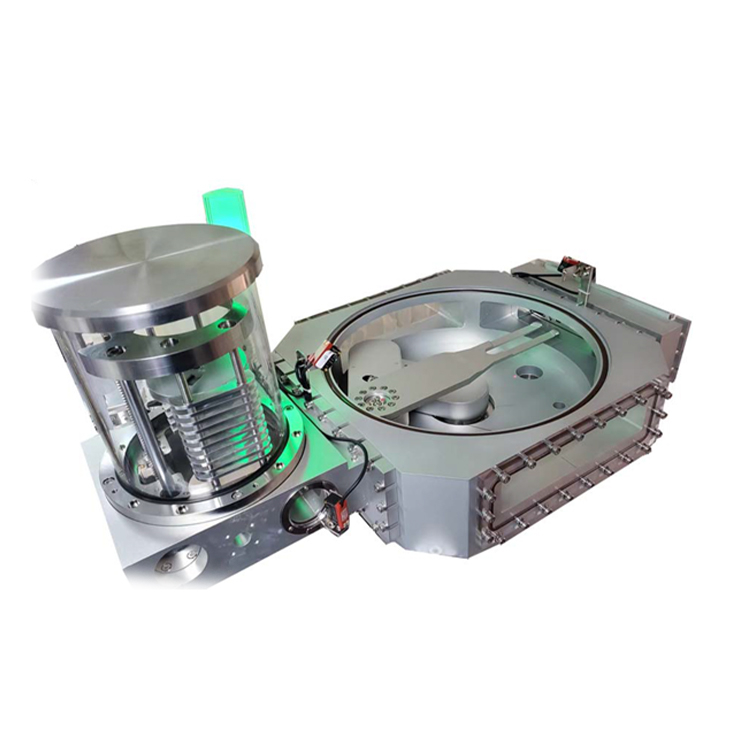

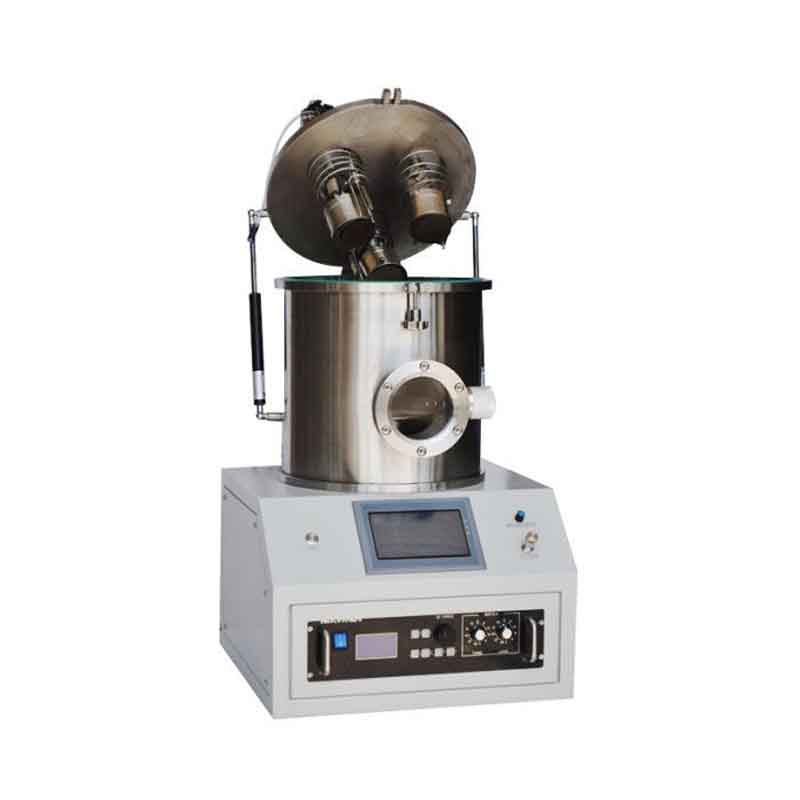

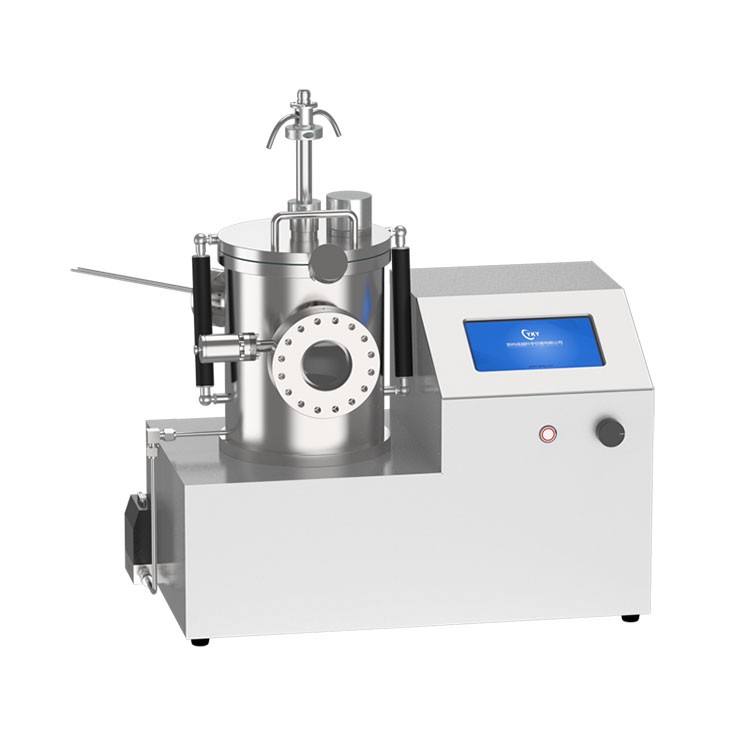

Magnetron Sputtering Head | 1.Two 2" Magnetron Sputtering Heads with water cooling jackets are included

One is connected to RF power supply for no-conductive materials

Another is connected to DC sputtering power source for coating metallic materials |

2.Target size requirement: 2" diameter |

3.Thickness Range: 0.1 - 5 mm for both metallic and non-conductive targets |

4.One stainless steel and one Al2O3 ceramic targets are included for demo testing |

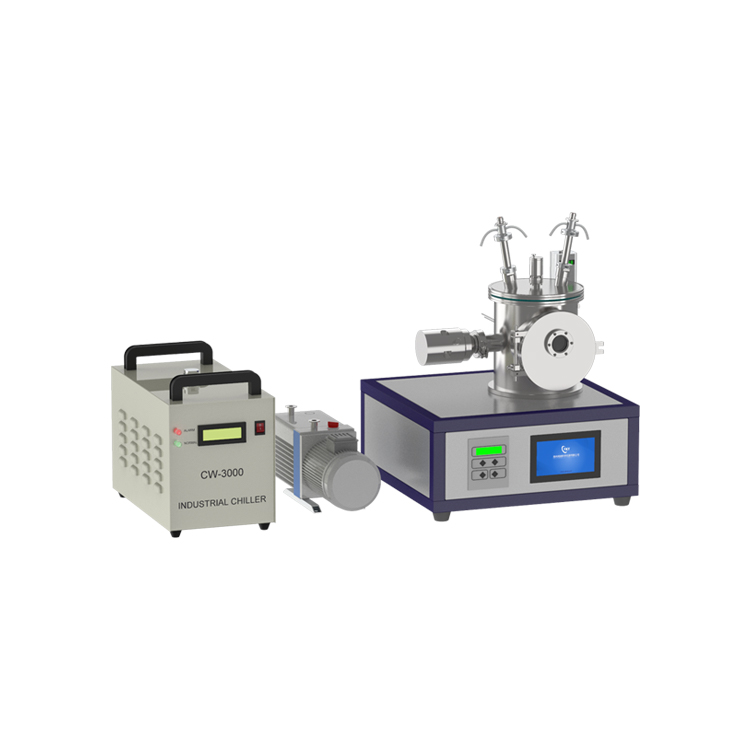

5.Head Water Cooling: 10ml/min water flow required, and one 16ml/min digitally

controlled recirculating water chiller is included for cooling both magnetron sputtering

heads |

6.Customized coater: Two DC head without, RF sputtering, RF head without

DC sputering,3 RF head are available upon request |

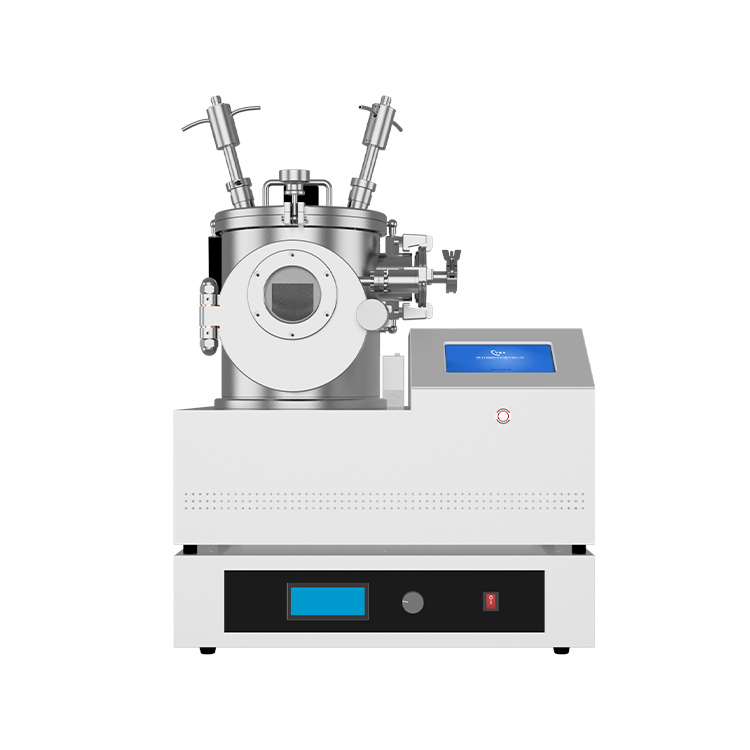

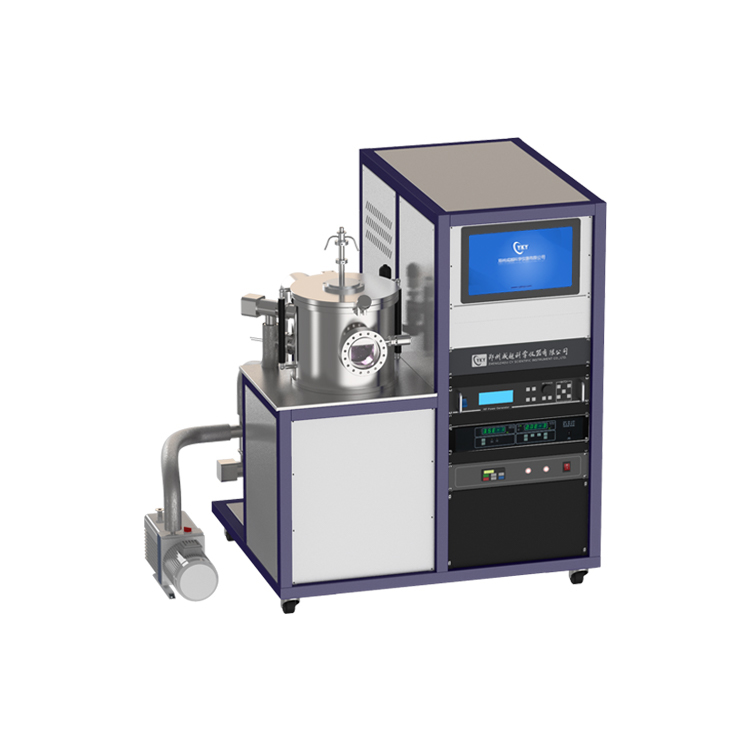

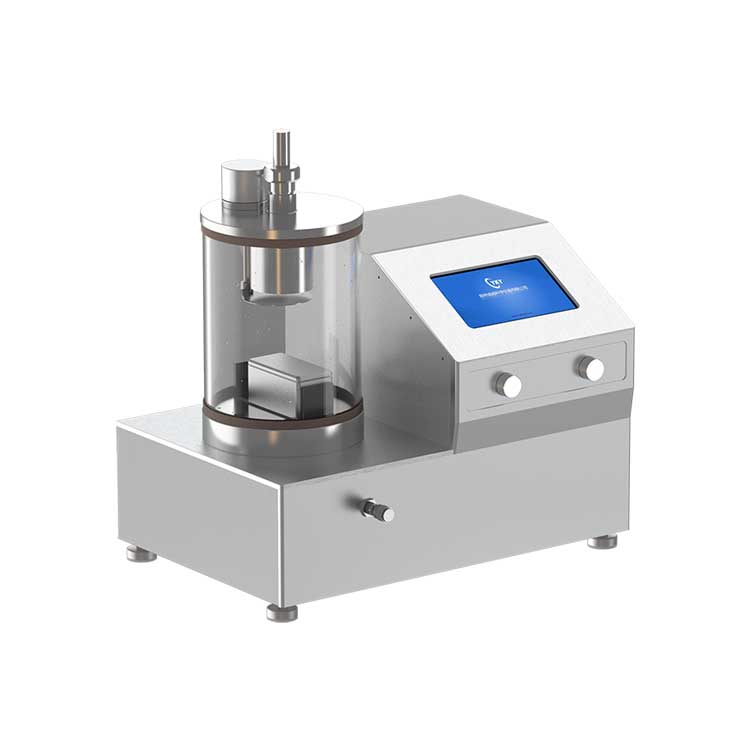

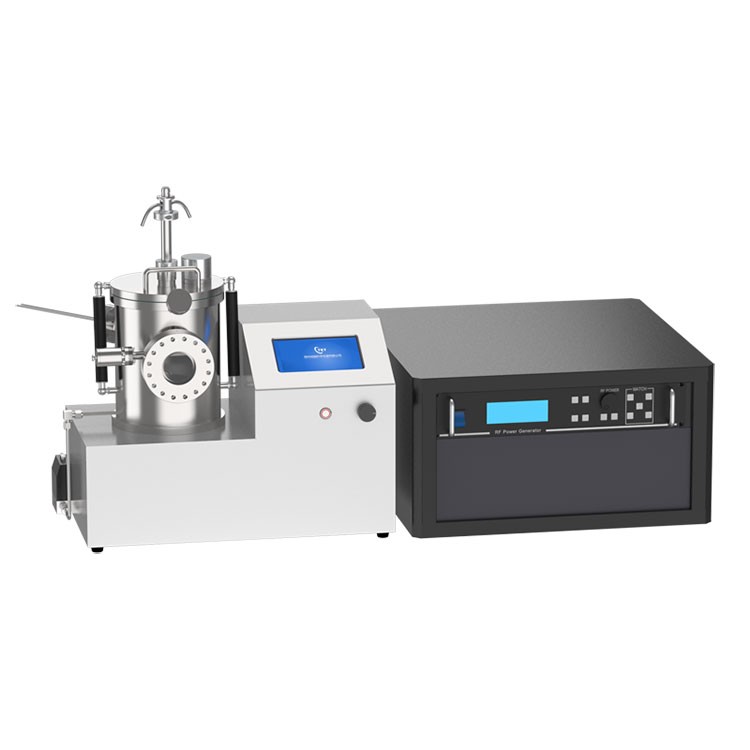

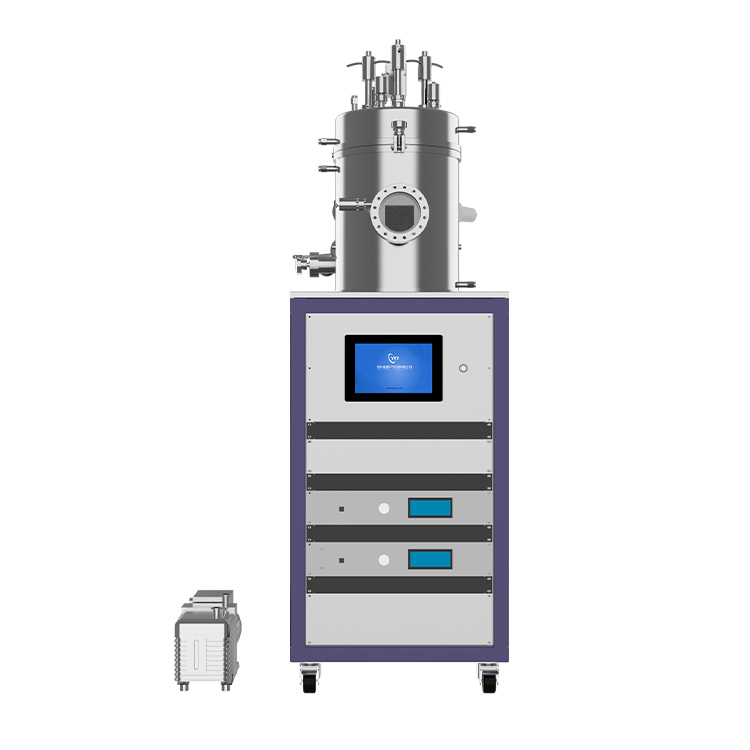

Vacuum Chamber | 1.Vacuum Chamber: 300 mm Dia x 300 mm height, made of stainless steel |

2.Observation Window: 100 mm diameter |

Sample Holder | 1.Sample holder size: 140mm dia. for. 4" wafer max |

2.Sample holder rotation speed is adjustable: 1 - 20 rpm for uniform coating |

3.The holder temperature is adjustable from RT to 500°C Max with accuracy +/- 1.0 °C |

Gas Flow Control | 1.Flow rate: 200 ml/min max. |

2.Flow rate is adjustable on the 6" touch screen control panel |

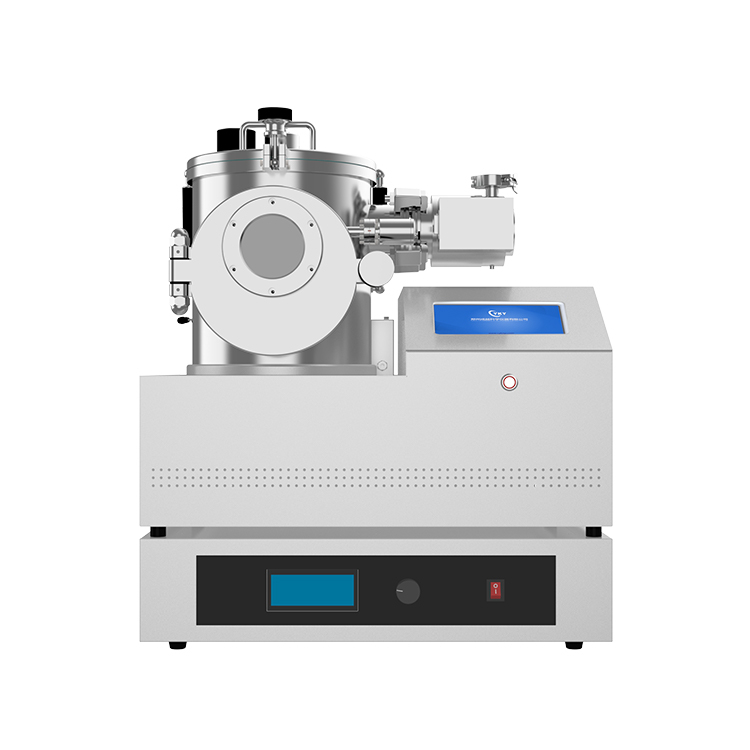

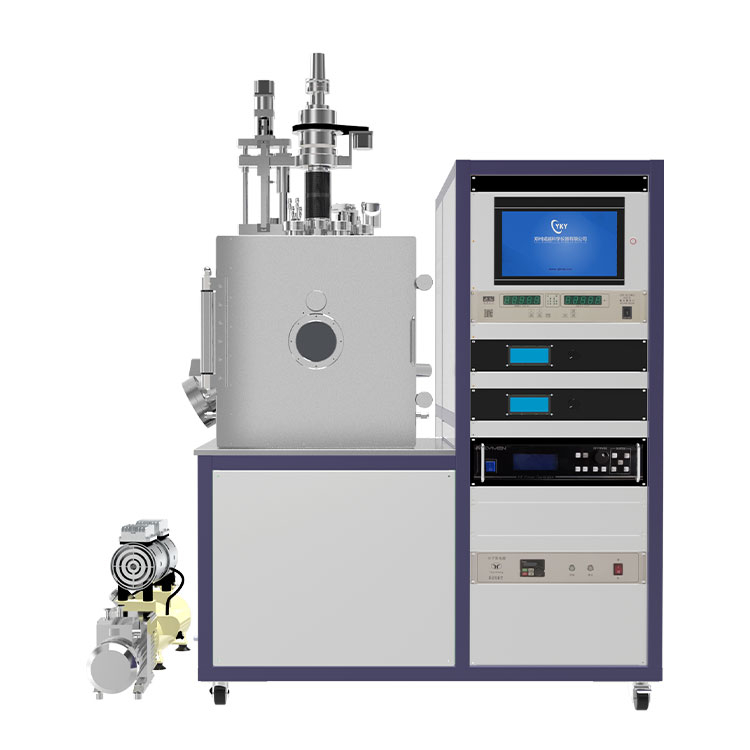

Vacuum Pump Station | High speed turbo vacuum pump system is directly installed on the vacuum chamber

for max. vacuum level |

Heavy duty dual stage mechanical pump is connected to turbo pump for faster

pump speed |

Mobile pump station is included and the compact sputtering coater can be put on

top of station |

Max. vacuum level: 10^-6 torr with chamber baking |

Thickness Monitor | One Precision quartz thickness sensor is built into the chamber to monitor coating

thickness with accuracy 0.10 Å |

LED Display Unit outside chamber can: |

Input material to be coated according to data base included |

Display total thickness coated and coating speed |

5 pcs quartz sensors (consumable) are included |

Water cooling is required |

Overall Dimensions | L6600mm× W660mm× H1200mm |

Application Note | In order to remove oxygen from the chamber, suggest you use 5% Hytrogen + 95 %

Nitrogen to clan chamber 2-3 times, which can reduce oxygen to below 10 ppm |

Please use > 5N purity Argon gas for plasma sputtering. Even though 5N purity Ar, usually contain 10- 100 ppm oxygen and H2O |

Net Weight | 160 kg |

Warranty | One years limited warranty with lifetime support |